Mechatronic and Human-Technology Systems

Simulation software is an essential requirement for virtual development of mechanical and mechatronic products as well as for planning, adaptation and optimization of processes involving interactions between humans and their environment.

In this research field, the R&D activities of the former Institute for Mechatronics e. V. are continued. This includes the development and application of software for modelling and simulating the dynamic behaviour of mechanical and mechatronic systems as well as for the digitization of human movements and human-machine interactions.

We use our software products and related services in our own R&D projects as well as in cooperation projects with other research institutions and industrial partners. We offer the software and services for sale to external interested parties.

Simulation of the dynamics of mechanical and mechatronic systems

Simulation software can be used to develop virtual prototypes of mechanical and mechatronic systems and to simulate their dynamic behavior even before the first real prototype is available. Typical fields of application for such simulations are mechanical and plant engineering, equipment manufacturing and vehicle construction. Especially in industries where the implementation of real prototypes is very costly, simulation plays an essential role in the product development phase.

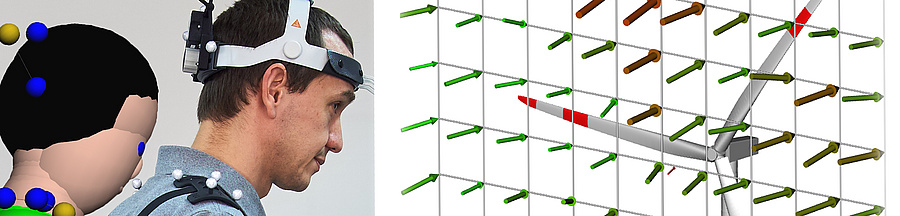

For this purpose, the alaska/MultibodyDynamics software is developed. Our customers use it for example in the development of wind turbines. The simulation models that are used depict such plants as complex mechatronic systems including sensors, actuators and controls. The large number of simulations performed is not limited to virtual commissioning, but also simulates a wide variety of events during production operation.

In addition to the general-purpose software alaska/MultibodyDynamics, we develop application- and customer-specific software. One example is the FlexSim software for simulating the assembly and loading of highly flexible one-dimensional components, such as hoses and cables.

Digitalization of movements and interactions

In certain products and processes, people play a major role as users or as actors. Digital human models (DHM) are used to fulfill this role into account as already during the computer-based development of products and planning of processes.

We have been developing the digital human model Dynamicus for many years and not only for the applications mentioned above. The model can be used as a component in simulation models for the general-purpose software alaska/MultibodyDynamics as well as in application-specific software.

To capture human motions and interactions with the environment, we use a workflow that we are continuously developing. This includes the integration of motion capture measurement technology. We use force measurement sensor technology for capturing interactions with the environment,. Special software saves the movements and interactions and transforms them to the DMM. The movements and interactions digitized in this way are available for subsequent computer-based investigations. both when processing research questions in the area of product development and process planning and for questions from sports science, rehabilitation and ergonomics.

In addition to capturing and processing real movements and interactions, we have extensive expertise in generating digital synthetic human movements, taking into account interactions with virtual environmental elements. For this purpose, we develop software that is in industrial use in vehicle development.

![[Translate to Englisch:] www.sig-forschung.de](/fileadmin/_processed_/8/1/csm_SIG_Logo_01_0f38ea6992.jpg)

![[Translate to Englisch:] www.zuse-gemeinschaft.de](/fileadmin/user_upload/icm/logos/icm_logo_zuse.png)