Together with our partners from industry and science, we work on innovative products and processes for mechanical and plant engineering. Our goal is to combine expert knowledge and digital data and to support SMEs in particular on their path to digitalization.

Mechanical and Plant Engineering

As an institute for applied research, we advance developments in mechanical engineering. In response to customer requests, we design new machines, also from a technological perspective. Since these projects can be high-risk, we explore public funding opportunities and, together with our partners and clients, assess suitable approaches. If needed, we coordinate all necessary disciplines in-house to support funding applications.

Technology development

Together with its partners, ICM offers the opportunity to test, evaluate, and apply various manufacturing processes. In-house and partner test stands are available for this purpose. We are happy to work with you to develop new, innovative processes for your application.

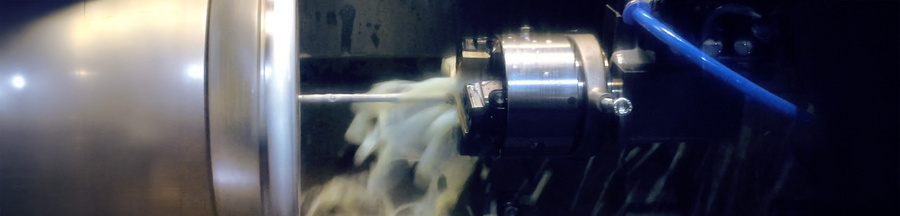

Hydroforming

Hydroforming (IHU) is a predestined process for implementing resource- and energy-efficient manufacturing. It enables the integration of multiple subprocesses into a single press stroke, shortening process chains and allowing for the production of high-precision components tailored to specific load requirements.

In the field of hydroforming, ICM has specialized in force-fit and form-fit joining, the use of dissimilar steels at room temperature, the application of multi-cavity tools for small and thin-walled components, and the creation of localized material accumulations.

Medical Technology

We offer tailored solutions that meet the highest standards of quality and safety while driving medical innovation forward.

Our core focus areas:

Medical device development: From concept to market-ready product – always in compliance with all relevant regulatory requirements, especially the Medical Device Regulation (MDR).

Simulation and analysis of medical applications: Our expertise spans both human and veterinary medicine, supporting the precise development of medical systems.

Eye diagnostic device

Foundry Technology

Our solutions for the foundry industry include the development of innovative special casting processes based on low-pressure casting technologies. These ensure high dimensional accuracy, tailored property profiles, and excellent surface quality of cast components in specialized applications. From sand casting and permanent mold casting to high-precision investment casting, we offer customized solutions tailored to your specific requirements.

Welding technology

In our state-of-the-art training and application center, we develop innovative solutions for your demanding welding tasks. By automating various welding processes (e.g., MAG/MIG, CMT, TIG, laser, and resistance welding), we improve quality and productivity in production. Feel free to contact us!

Our Services

In the field of plant engineering, we offer customized solutions for a wide range of industrial applications. Our expertise ranges from planning and design to assembly and commissioning of complex systems.

Feasibility studies

The funding landscape is often perceived as complex and opaque. Assessing the potential of a project can be equally challenging — especially for companies lacking the time or in-house expertise.

We bridge this gap by guiding you through every critical step: from initial analysis and feasibility studies to risk and potential assessments. Our experts ensure each project is evaluated with a focus on sustainability and long-term viability.

We also support you through market studies and patent applications, drawing on our many years of experience in both areas.

CE & Machine Safety

Risk Assessment & Machinery Safety

Risk assessment and machinery safety are essential for ensuring safe and reliable industrial operations. Through systematic analysis, potential hazards are identified and evaluated to develop targeted safety measures that protect both people and equipment.

We place safety first. Our experts offer comprehensive services in risk analysis and machine safety — from hazard identification and risk evaluation to tailored safety concepts. With our structured approach and preventive strategies, we help ensure your machines operate both efficiently and safely.

New EU Machinery Regulation

The new Machinery Regulation (EU) 2023/1230 replaces the previous Machinery Directive and introduces several updates aimed at improving safety and simplifying compliance.

Mechanical and electrical engineering

Mechanical design and simulation are the foundation of innovative product development. Precise engineering and advanced simulation techniques enable the creation of complex components and systems that meet the highest standards of functionality and reliability.

Modern simulations allow for detailed analysis and optimization of physical properties, loads, and real-world behavior already in the design phase — resulting in solutions that are both technically and economically compelling.

Simulation & Calculation

Our core simulation capabilities include FEM for forming technology, biomechanical modeling, and complex multiphysics simulations – all developed through the collaboration of experts across engineering, data science, and applied research.

The team has extensive experience in applying advanced simulation and data analysis methods in mechanical and plant engineering, as well as in human–technology interaction. We combine proven methodologies with innovative approaches to develop customized solutions tailored to your specific needs.

With our solid data science expertise and interdisciplinary approach, we provide robust decision-making support – from product development to process optimization.

![[Translate to Englisch:] Verteilerbalken in verschiedenen Größen](/fileadmin/_processed_/4/5/csm_OEFFA_alle-rohrfoermig_WEISS_2024-11-21_SSP_e343099b8d.jpg)

![[Translate to Englisch:] Bipolarplatte](/fileadmin/_processed_/3/2/csm_OEFFA_Bipolarplatte02_2024-10-21_SSP_ef938823aa.jpg)

![[Translate to Englisch:] IHU Bauteil für einen Stecker](/fileadmin/_processed_/4/6/csm_OEFFA_IHU_Steckerfertigung_2025-03-18_SSP_7edf1faed7.jpg)

![[Translate to Englisch:] www.sig-forschung.de](/fileadmin/_processed_/8/1/csm_SIG_Logo_01_0f38ea6992.jpg)

![[Translate to Englisch:] www.zuse-gemeinschaft.de](/fileadmin/user_upload/icm/logos/icm_logo_zuse.png)