In addition to high energy prices, rising production volumes, increased product diversity, and customer customization are shaping development trends in manufacturing. Cost-effectiveness and the prudent use of resources require new approaches to planning and production tracking. We will support you on the path to the digital factory and the mplementation of human-machine interactions specifically tailored to the requirements of small and medium-sized enterprises.

Data Science

The digitalization of production processes and the implementation of energy-efficient manufacturing are directly linked to the analysis of large amounts of data. Due to the abundance and diversity of this data, the application of well-founded algorithms and processes is often necessary to generate knowledge from it. We collaborate with companies on researching the application of machine learning methods and AI algorithms. In this way, we pursue the goal of collecting relevant process data, evaluating it efficiently, and presenting it profitably.

Our Services

Upgrade your existing systems and become IoT-enabled.

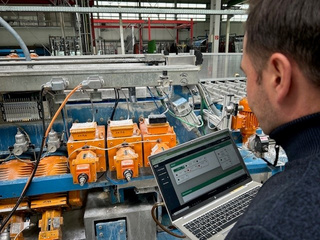

For this purpose, we use specially developed measurement modules that can be easily integrated into existing production processes and enable continuous process monitoring. The recorded energy parameters will be analyzed and evaluated using suitable algorithms and can be displayed using user-specific software.

Condition Monitoring

The condition monitoring system is used to extract energy data from drives and machines. Existing systems are transformed into the digital world with the help of our solutions. The recorded data is reduced to a minimum, classified, and presented in a user-specific manner. This can be used to reduce plant downtime, perform preventive maintenance, or further expand existing service concepts.

What we offer:

- monitoring of single drives

- optimization of processes

- avaluation of data and its targeted use

- create your own platform of industry 4.0

- IoT Retrofit - detect information and key performance indicators of existing drives fpr upcoming investments

Based on our experience, we are happy to assist you as a competent partner in the planning and implementation of your digitalization projects. We can also create customized visualization interfaces to capture the most important information at a glance.

![[Translate to Englisch:] www.sig-forschung.de](/fileadmin/_processed_/8/1/csm_SIG_Logo_01_0f38ea6992.jpg)

![[Translate to Englisch:] www.zuse-gemeinschaft.de](/fileadmin/user_upload/icm/logos/icm_logo_zuse.png)