Equipment

The ICM e.V. combines several development environments under one roof. This enables not only fundamental research, but also the testing of newly developed solutions all the way up to the prototype.

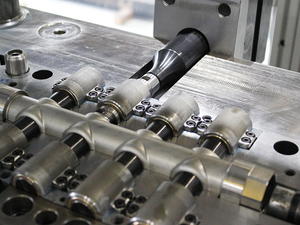

Forming

The field of forming technology is one of our core competencies. Our main focus is on the constant innovation of the forming processes. In this field of development we have the following equipment to our disposal:

- Hydroforming- Lightweight Press

- Hydraulic clamping device for forming small components with high-pressure generation unit

- Flexible Forming center (hydraulic multi-purpose press)

- Experimental die for forming thin-walled tubes

- Vacuum, inert gas, and temperature control system for superplastic forming

Flexible Automation

We have been researching in the field of flexible automation for several years. We would like to use this environment specifically to bring it to small and medium-sized enterprises. It offers many advantages not only to large-scale industry. SMEs can also benefit from its use. In this field of development we are researching innovative applications and have the following equipment at our disposal:

- Mobile robot and handling system (Kawasaki industrial robot, tool changing station, mobile base frame )

- HRC-capable mobile transport system (MIR and UR5)

- HRC-capable mobile transport system (Beldrive and Fanuc)

- Classical automation (3-axis gantry, robot cell, vibratory bowl feeder, conveyor belt)

- HRC Demonstration Center “Belt Assembly”

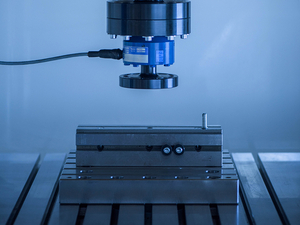

Machine Diagnostics

Another focus of ours is put on machining processes that we can examine more closely using our equipment in machine diagnostics:

- Vibration measuring system

- Cutting force measuring system

- Acceleration measuring system

Material Testing

Mechanical and plant engineering requires professional materials testing. The special purpose machines are at the center of our interest. Assemblies must fulfil many parameters in order to meet the requirements for industrial use. Our material testing laboratory provides the necessary development environment:

- Machine for safe cutting of test components without heat input

- Machine for surface preparation of embedded samples

- Hot embedding press

- Hardness tester HRC

- sample cleaning and desiccator

- Digital microscopes

- Climatic cell (2.5 x 2.5 x 4m size, +40 to -10 degrees Celsius possible)

Bearing Inspection

Assemblies contain specially adapted bearings. Our expertise in the field of variable bearing preload forms the development environment to investigate bearings in individual mechanisms of operation:

- test rig

- Rotor dynamics test rig

- Bearing wear test rig

- Precision universal testing machine

- (force range up to 500N, 10kN and 100kN)

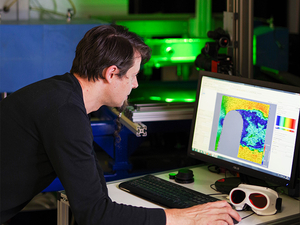

Flow Measurement

In the development environment of flow measurement, we investigate the flow behavior of components under various conditions and in diverse media in order to draw process engineering conclusions and improvements. In this we work with the following technical equipment:

- System for measuring velocity fields in flowing media (PIV system)

- Test rig for fluid mechanical investigations

- radial bearing test rig with precision spindle for tribometric tests

- dynamic load test rig for rotational components

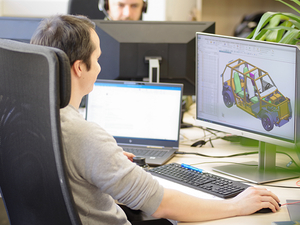

Calculations, Analysis, Simulations and Data evaluation

ICM e.V. combines numerous experts in software-based design. We perform calculations, analysis, simulations and data evaluation using current software and incorporate data from the other development environments into our considerations. Thus we can achieve important market-relevant findings that lead to new research considerations. We use the following software for this:

- Matlab

- KISSsoft

- COBRA

- Pro Engineer (CREO)

- Solid Works

- HBB NX

- Designer ANSYS: Enterprise Mechanical

- Design Modeler

- MSC Marc Mentat

- Simulation X

- EPlan NI

- LabView / Realtime

- NI Vision

- NI CompactRIO

- NI DIAdem

Digitization of Movements and Interactions

The model-based analysis and synthesis of human movements and interactions with the environment are based on data from real motion and interaction processes. The following equipment is available for measurement and data acquisition:

- Motion Capture System from ART with infrared cameras for capturing movements of test subjects and equipment.

- Finger Tracking System (ART) for tracking hand movements.

- Kistler Force Plates, e.g., for capturing ground reaction forces.

- 3D Force Sensors (Kistler) for measuring interaction forces.

- Measuring Probes (ART) for calibrating and mapping environmental elements.

- Sensor Mats from novel for detecting pressure distributions, e.g., on vehicle seats and wheelchairs.

- 3D Hand Scanner for generating geometry representations of equipment components.

Preliminary Research

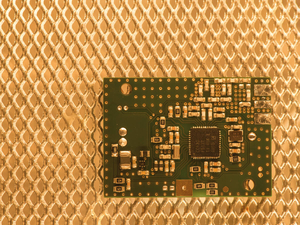

In order to bring preliminary research into reality, in many cases we develop the necessary hardware to prototype with individual electronic components. In order to implement and optimize this in the best possible way, we work with the following equipment:

- Spectrum Analyzer

- Measurement and sensor technology for various test benches

- Reflow oven

- Vector network analyzer

![[Translate to Englisch:] www.sig-forschung.de](/fileadmin/_processed_/8/1/csm_SIG_Logo_01_0f38ea6992.jpg)

![[Translate to Englisch:] www.zuse-gemeinschaft.de](/fileadmin/user_upload/icm/logos/icm_logo_zuse.png)